CNC Hungaria Kft. – Production and machine park introduction

CNC Hungaria Kft. was founded in 2014 and is a 100% Hungarian-owned, dynamically developing company.

Our colleagues have 20 years of professional experience in the sale of CNC-controlled and conventional machines, and our company has an extensive network of contacts. In addition to our current activity – the distribution of metalworking machines – we also extend our profile to the production of tools and parts.

We have successfully completed 2 European Union tenders for production machines, the amount of the received support: 66.916.308 HUF.

We have the BISNODE “A” certificate. Cnc Hungaria Kft. belongs to the best, most reliable 9.82% of Hungarian enterprises.

Our company’s headquarters and manufacturing workshop are located on its own site in Tát, Komárom-Esztergom County.

We have a license for the production of military products, the provision of military services and for military trade.

The expertise and experience of our employees and the responsible management of our managers are the guarantee that we also ensure the reliability, precision and customer orientation in our commercial activities in production. With our innovative approach and flexibility, we strive to meet the ever-changing market needs in order to build and maintain long-term relationships with our future partners.

As a reliable and competent partner, our company offers industrial services in the following areas:

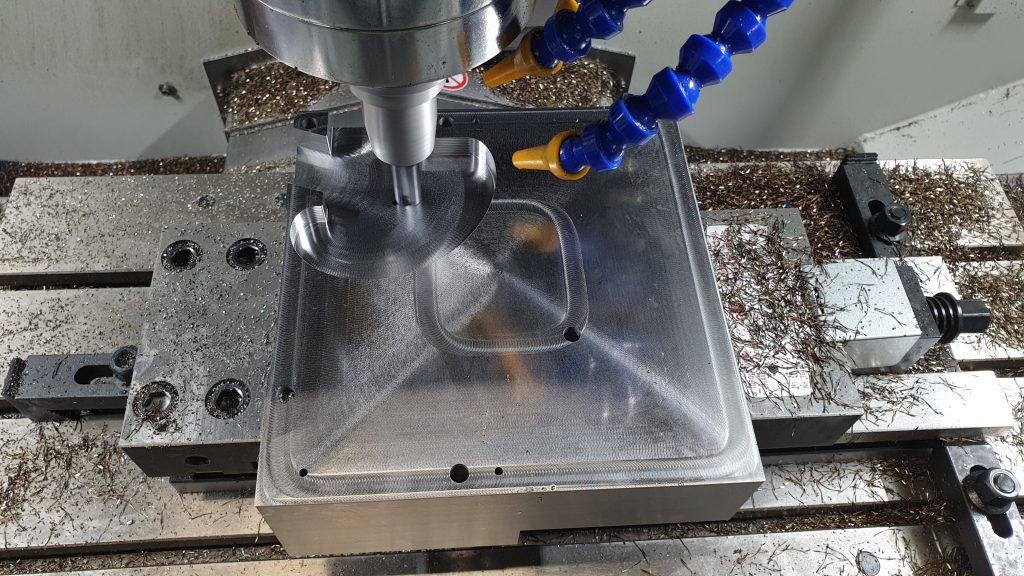

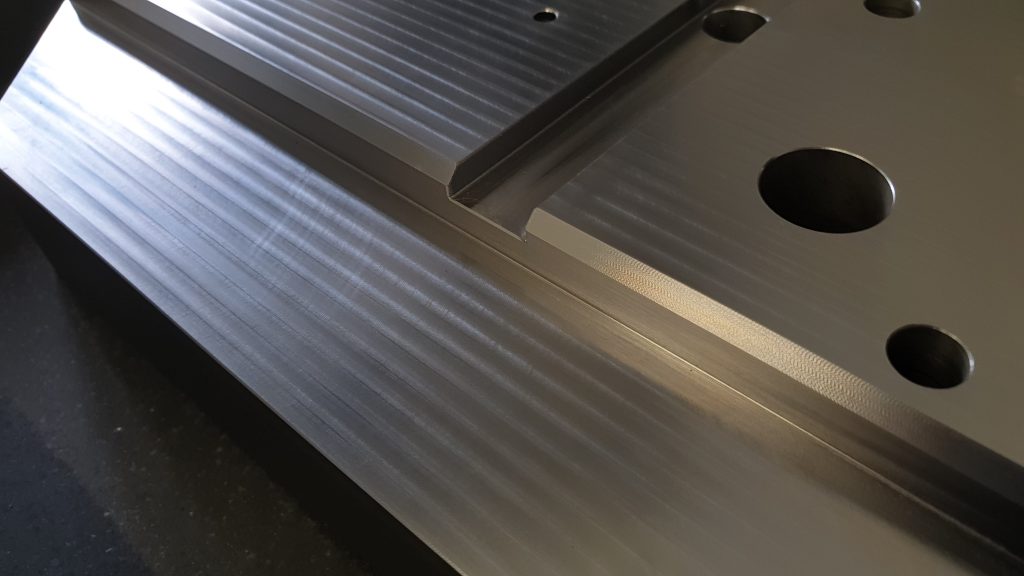

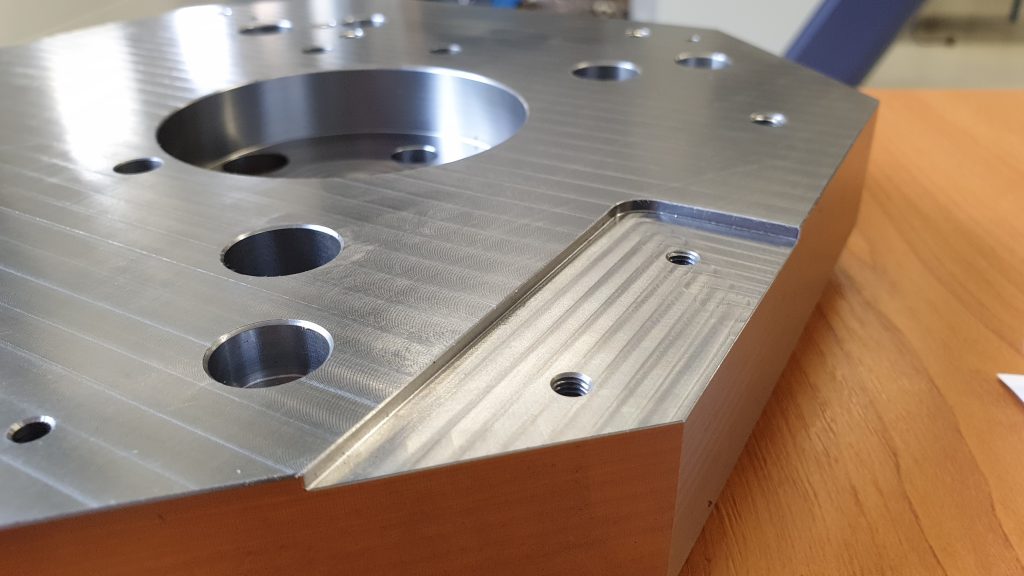

- precision individual and small series component production

- design

- prototype production

- production of cold and hot forming tools

- tool repair, modification, maintenance and optimization

- automation

- device and custom made special purpose machine design, production

- series production

We strive to develop a strategic partner status that provides maximum flexibility in all respects. We perform all tasks by optimizing, with maximum integration of quality conditions, so we can do it quickly and efficiently

- to make an offer

- to accept an order

- to confirm deadlines and meet them.

We send a regular report on the status of our received orders.

We use Siemens NX software for our design, optimization and manufacturing processes.

Upon customer request, we provide the complete 2D / 3D documentation of the tool and / or component production, in any format, together with a measurement report.

A special advantage is that the planned times of the work performed can always be compared with the workers’ and machine times spent, so that in addition to the time statement, the production efficiency of the workers can also be measured.

The use of the NormaX production management system provides a solution specifically for tracking, organizing and controlling tool production, individual component production, remanufacturing and series production. It solves the documentation and retrieval of production during production. With the help of the program, reports can be made on the efficiency of production and workers, the time spent on work, and the utilization of machines.

The quality of our work is ensured by a team of highly qualified specialists with decades of experience, modern machinery and state-of-the-art technology.

Thanks to our high level of professionalism and our geographical location, we are able to undertake the production related to the above areas of activity and the necessary planning with an extremely short lead time.

If required by customers, we are also open to expanding and developing our machine park and manufacturing plastic products. Together with our partners and subcontractors, we can undertake any kind of production.

We look forward to hearing from you as soon as possible!

The team of CNC HUNGARIA KFT.

Our current fleet (machine park):

SODICK ALC400P precísion wire erosion machine – 1 pc.

Year: 2020

Travel (X, Y, Z): 400 x 300 x 250 mm, accuracy 0.001mm

U/V axes: 150 x 150 mm

Max. workpiece weight: 500 kg

Internal size of work tank: 850 x 610

Dimensions of the machine: 2 115 x 2 500 x 2 230

Machine weight (kg): 3 400

Conical cut: ±25°

Usable wire diameters (mm): Ø 0.10~ Ø 0.30

Wire tension (N): 3~23

Max. wire speed (mm/sec): 420

SODICK AG40L diesinking machine – 1 pc.

- With linear motors on the X, Y, Z axes

- Linear glass measuring rod on each axis

- 32x tool changer

- SVC circuit for super fine surfaces and graphite electrode machining

- Ceramic parts

- LN2 with CNC control

Year: 2020

Travel X/Y/Z (mm): 400 x 300 x 270, accuracy 0.001mm

Worktable size (mm): 600 x 400

Max. workpiece weight (kg): 550

Distance between the floor and the upper plane of the table (mm): 83

Dimensions of the machine (mm): 1662 x 2490 x 2320

Max. electrode weight (kg): 50

Machine weight (kg): 4100

MITUTOYO Crysta Plus M 776 manual coordinate measuring machine – 1 pc.

Manual coordinate measuring machine with high measuring accuracy. The CRYSTA-Plus M series is wide ensures the construction of the optimal configuration in a range of sizes.

• Easy and simple operation thanks to the air bearing.

• Fine positioning option

• With MCOSMOS software

Year: 2020

Travel: 700 x 700 x 600 mm

Max. workpiece weight: 500 kg

Machine weight: 1560 kg

Our newly introduced, reliable metalworking machines, marketed under the name TAATH, are German-designed and manufactured in strict accordance with the CE standard, using Japanese and Taiwanese parts. All our machines are characterized by high accuracy and long life. Our machines can be viewed and tested at our site, and the accuracy of the test pieces can be checked with measuring machine. Detailed descriptions are available on our website (www.cnchungaria.hu).

TAATH BL-Y600 machining centre – 2 pc.

- · Designed by German engineers

Year: 2019

Table size: 800 x 400 mm

Travel X, Y, Z: 600 x 400 x 450 mm, accuracy 0.005mm

Spindle cone: BT 40/ϕ120 mm

Spindle speed: 100-8000 RPM

Control: Siemens 828D

TAATH BL-Y855 5 axis (3+2) machining centre – 1 pc.

- Designed by German engineers

- Produced according to strict CE-standard

- Main parts are Taiwanese, German and Japanese

- High speed, high accuracy, long life

- Rigid frame, high stability, with FEA analysis

- C3 precision ball screws on all three axes

- Spindle nuts are pre-tensioned to minimize backlash for stable positioning and high repeatability

Year: 2020

Table size: 1000 x 550 mm

Max. table loading: 500 kg

Travel X, Y, Z: 800 x 550 x 550 mm

Spindle cone: BT 40/ϕ150 mm

Spindle speed: 100-12000 RPM

Control: Siemens 840DSL

Cooling through spindle

24 arm type tool magazine

Chip conveyor

TAATH BL-HK80B flat bed CNC lathe – 1 pc.

Year: 2020

Max. swing dia. over bed: Φ800 mm

Max. swing dia. over slide: Φ500 mm

Guideway width: 560 mm

Center distance: 1000 mm

X axes travel: 390 mm

Z axes travel: 760 mm

Spindle speed: 20-1120 rpm

Control: Siemens 828D

Max. workpiece weight: 900 kg

Tool turret type: horizontal 6 station

Hydraulic chuck 12”

Hydraulic tailstock

TAATH MK 7140 CNC grinding machine – 1 pc.

High precision

bearing spindles (accuracy class P4).

Precise V-type conductor, stable machining process.

Reliable hydraulic system, long service life

.

Year: 2019

Table: 1000 x 400 mm

Max. distance from spindle center to table surface: 575 mm

Wheel size: Ø 350 x 40 x 127 mm

Spindle speed: 1440rpm

Accuracy 0.001mm

BOMAR STG 320 GM saw – 1 pc.

Suitable for cutting various ferrous and non-ferrous metals. The structure provides stable and reliable performance and high precision. Ideal equipment for cutting medium and small items to size

Year of manufacture: 2002

Mitutoyo PV-5100 measuring projector – 1 pc.

The robust PV-5100 profile projector features

a vertical optical system with a large Ø 508 mm

projection screen and a built-in digital counter.

Measuring range XY table 200 x 100 mm

Elbo controlli NIKKEN, Sethy six: measuring machine – 1 pc.

External tool measuring range: diameter 400 mm, height 600

optical camera system for tool measurement and edge inspection with 30x magnification

15″ color tFt touch screen intuitive user interface

Computer equipped with INtel processor with UBUNTU linux operating system, SSD

Spindle movement with pneumatic shaft attachment and mechanical spindle braking

casing and support elements made of stainless steel

measurement resolution 1 μm√ base and column: natural ground granite: flatness <2 μm/m ISO/BT/HSK/VDI/Capto etc.

replaceable spindle

Running accuracy is constant within 4μm

powerful double Archimedean spiral spring suspension

99 CNC machine zero point management

toolData six software, a universal and comprehensive post processor

Tool management options

USB port for printer, LAN port for network communication

description in Hungarian, easy-to-use pictogram software

Cnc Hungaria Kft.